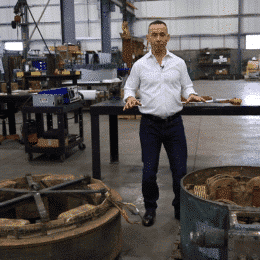

Metal Casting

Power cable reliability is critical to meeting your melt production goals. I2r POWER offers advanced solutions to the metal casting industry to keep your production schedules on track and increase reliability.

Maximum Electrical Power for Metal Casters

Your melting equipment runs at optimum electrical efficiency with minimal loss through I2r POWER custom cables and components. Here’s why:

- Engineering & Design Collaboration - I2r POWER works with you to solve design and thermal productivity challenges with advanced solutions to maximize electrical efficiency.

- Low Maintenance - With reliable products built to last, I2r POWER cables and components reduce maintenance and service-related chores.

- Expert Craftsmanship - Cables and components are manufactured to maximize power efficiency—built by hand from top-quality materials.

Advanced Power Cable Solutions for Electrical Efficiency

Power cable reliability is critical to meeting your foundry melt production goals. I2r POWER offers engineered power cable solutions for foundry casting with expertise in these applications:

Coreless Induction Melting

Channel/Holding Furnace

Auto Pressure Pour Systems

Graphite Stirring Rod Processes

Engineered for electrical efficiency and hand-built using top-grade materials, I2r POWER technicians craft your high-current induction cables to maximize power transmission.

Inherently more energy efficient than flexible wire conductors, rigid AC or DC bus systems are a high value, long lasting option for a variety of power transmission applications.

I2r POWER works hard to over-deliver on customer expectations. Every job is a custom, engineered design effort to fit your exact specifications. Let's talk solutions and how we can help maximize your electrical efficiency!