Electromagnetic Stirring (EMS)

Reliable performance time after time

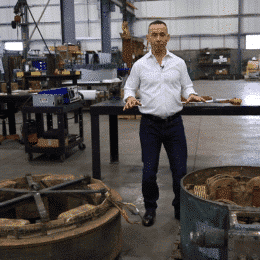

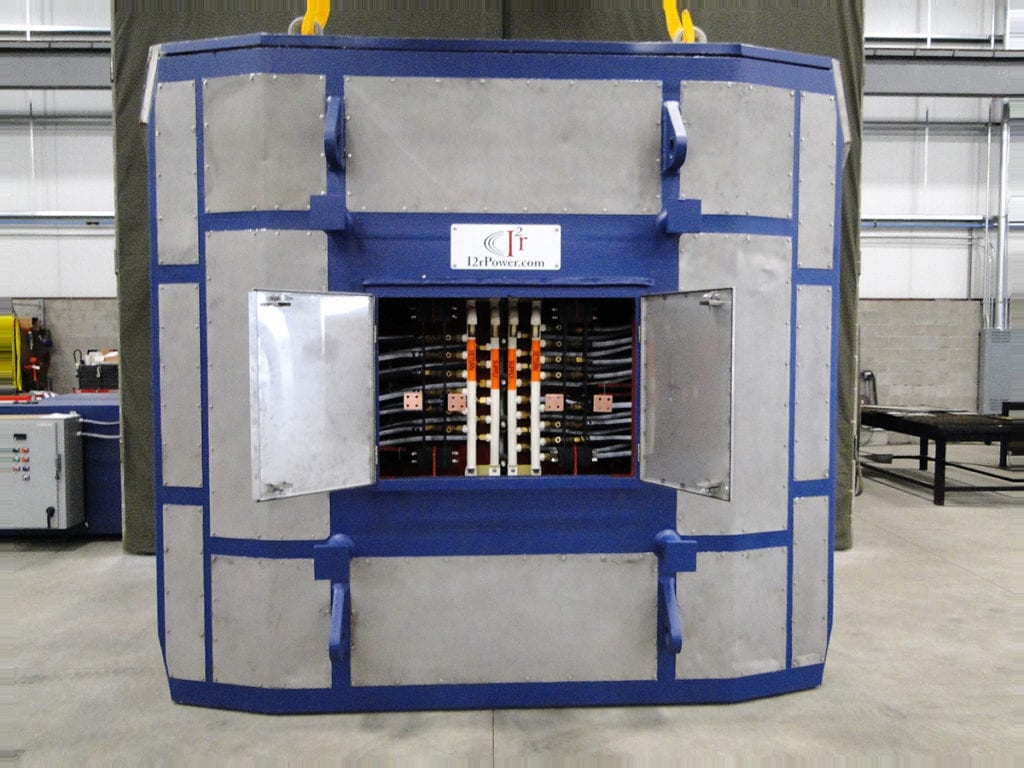

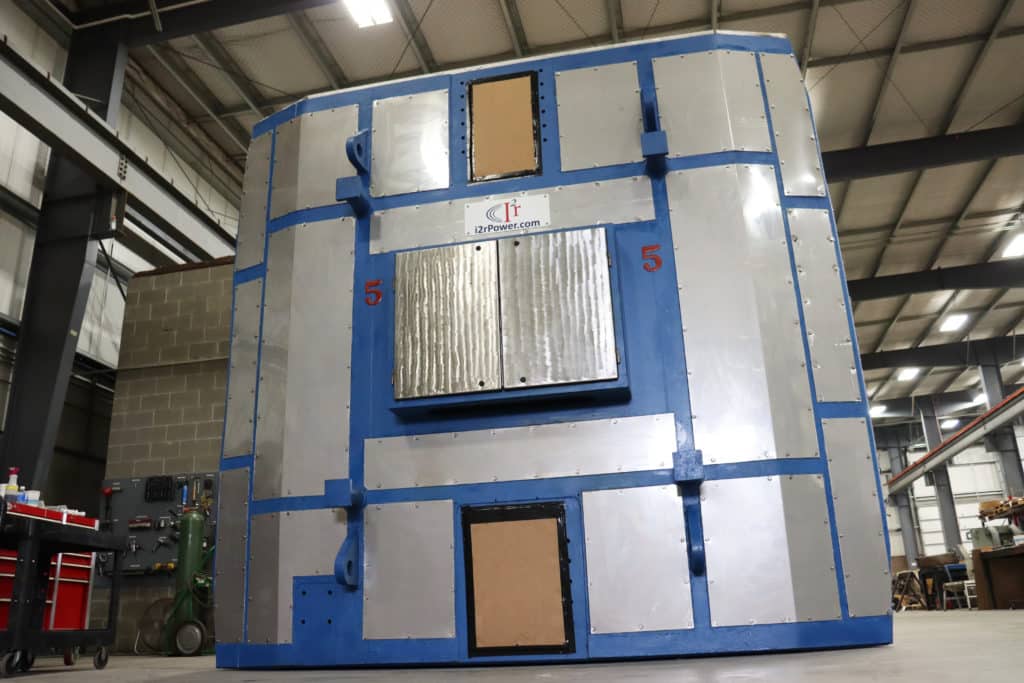

Protecting your device from collision and molten spill with key construction improvements are critical to efficient electromagnetic stirring. Entirely crafted to your exact needs, I2r POWER conducts complex continuous caster and ladle EMS service with more than 100 years of combined experience. Skilled technicians are familiar with various OEM devices and are well versed in demanding application conditions. Original equipment is routinely enhanced with design improvements to increase reliability and longevity.

When you are looking for design, build, retrofit, or custom applications, I²r POWER is your best choice for electromagnetic stirring.

Electromagnetic Stirring Video

Electromagnetic Stirring Series - Chapter 1: Caster Stirrers (2021)

Continuous Caster Stirrers

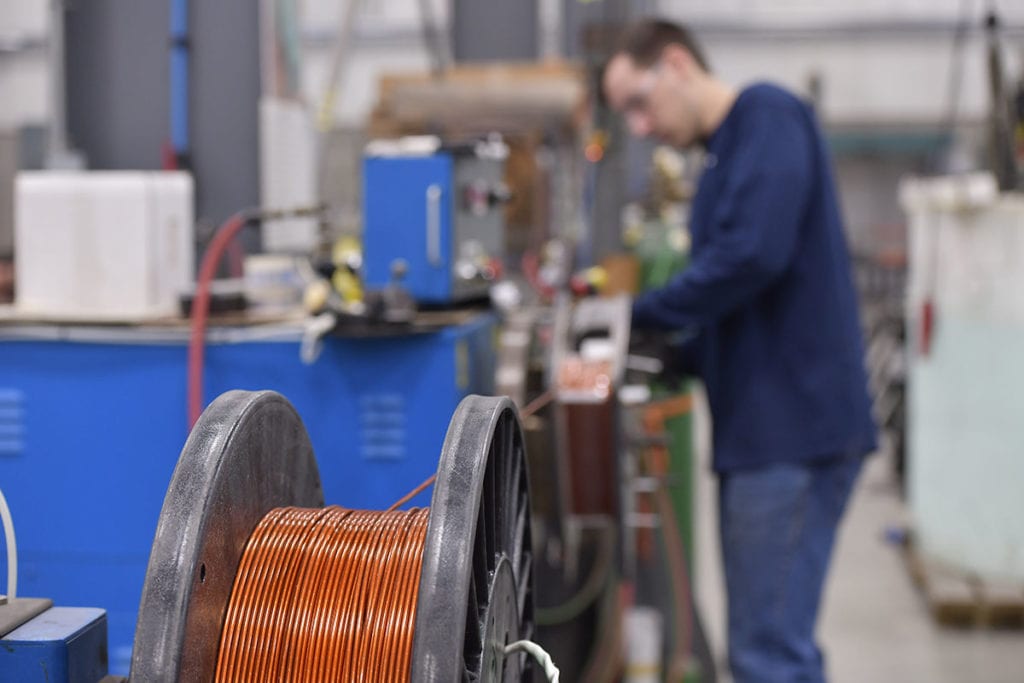

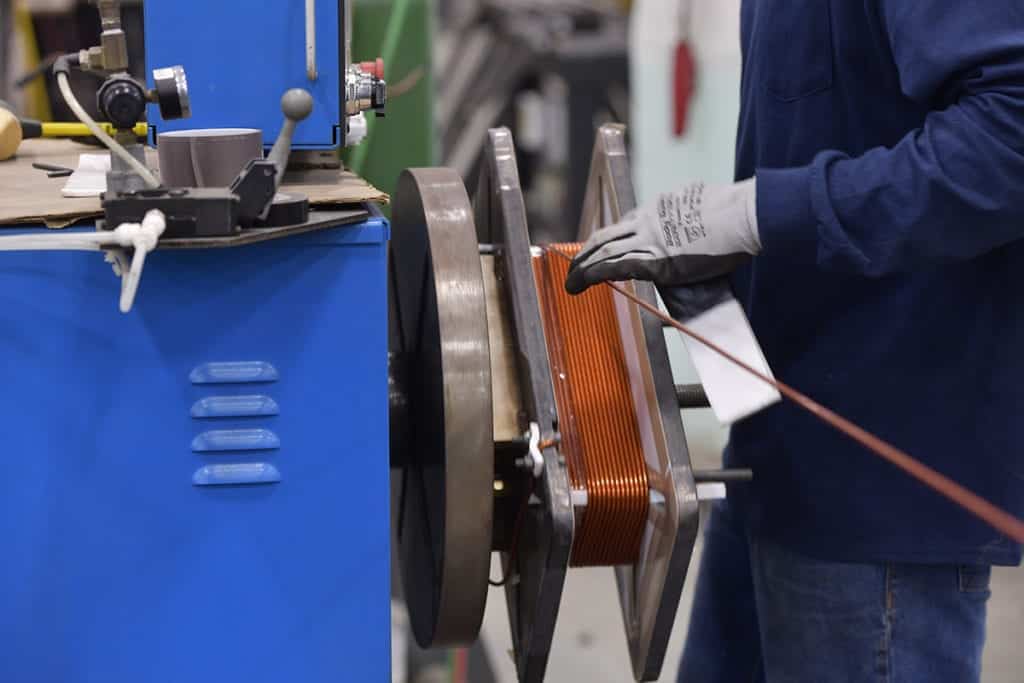

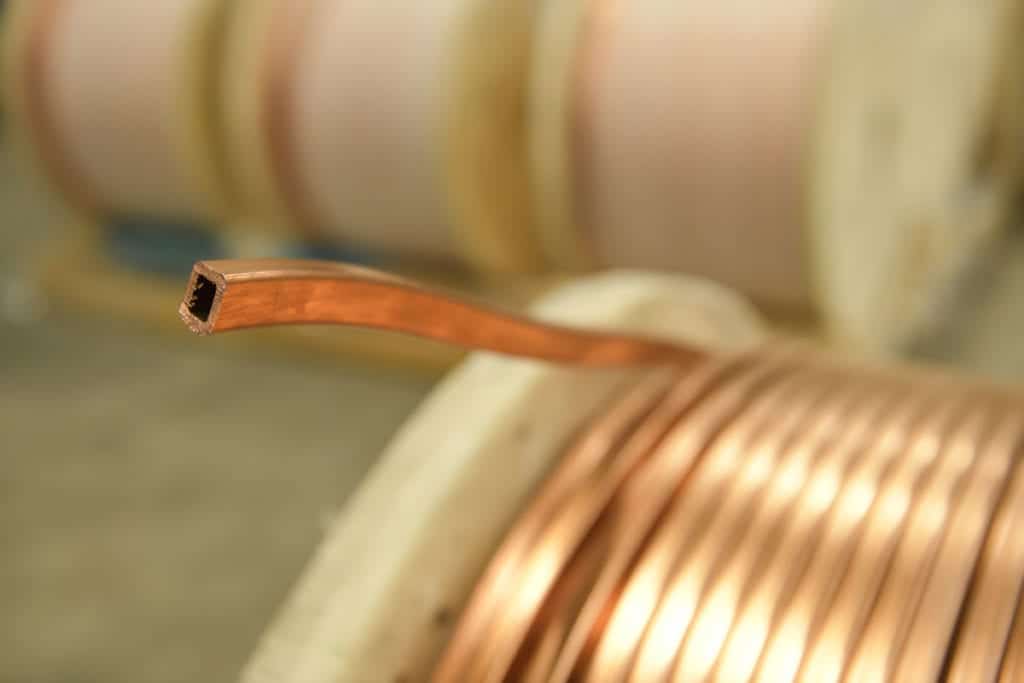

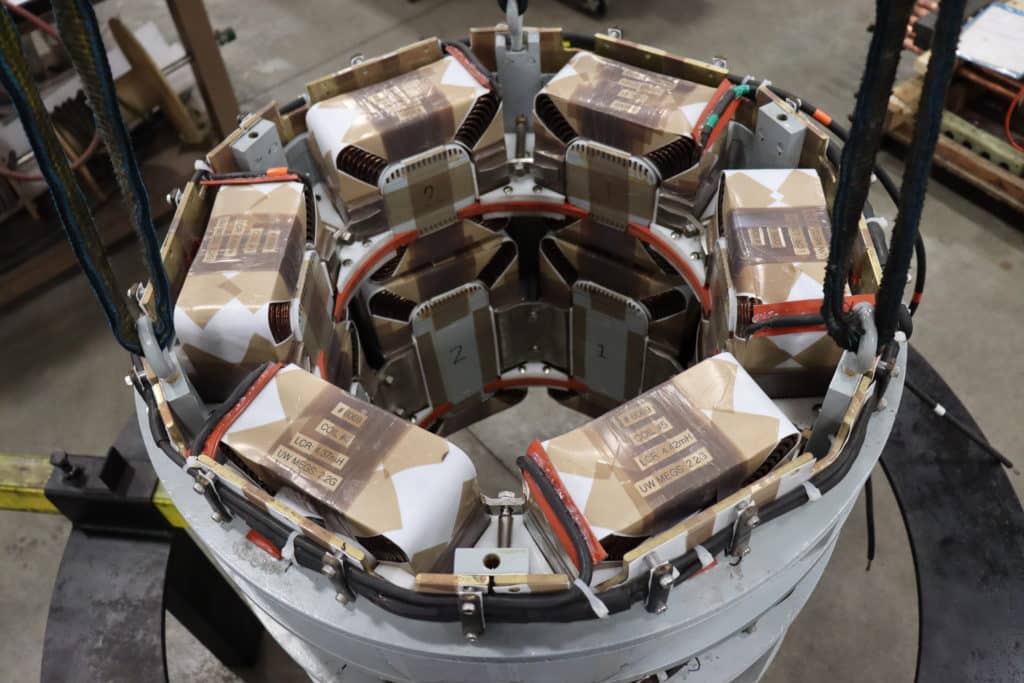

Coil failure and shorting can be prevented or minimized with proper magnet wire insulation systems. I2r POWER investigates and applies the best wire insulation systems to your EMS device for effective and reliable electromagnetic stirring. Skilled technicians understand your demanding operating conditions, and routinely make improvements to mold, linear and final stirrers for performance and longevity.

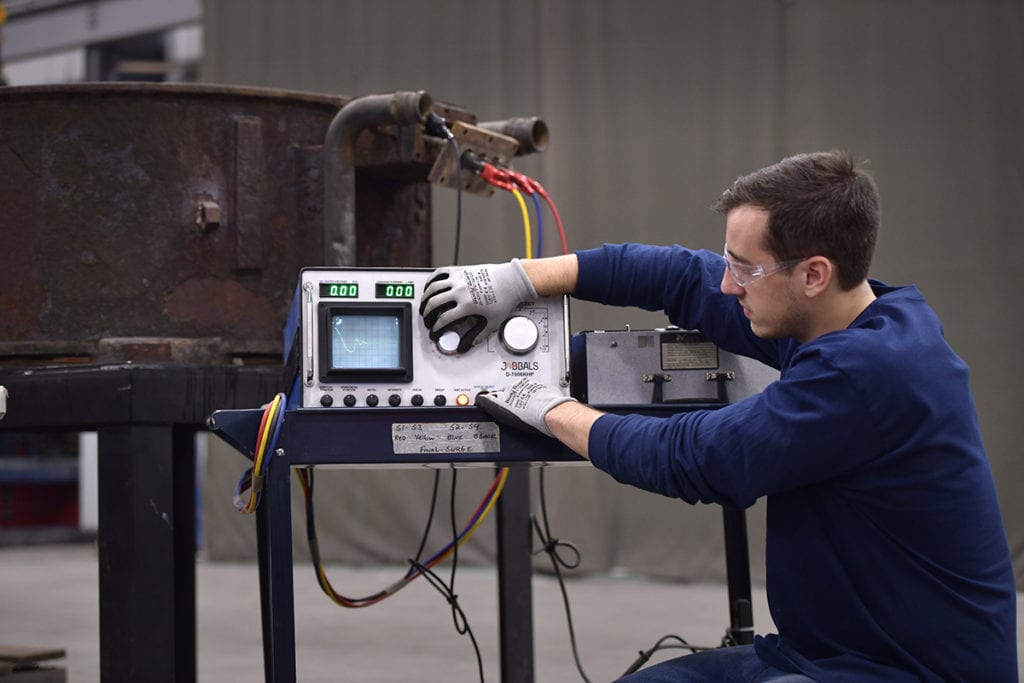

Frequent and multiple tests are conducted throughout the assembly of your caster stirrer including dynamic electrical testing in a water submerged state, as well as magnetic field orientation confirmation. All test results are forwarded to you.

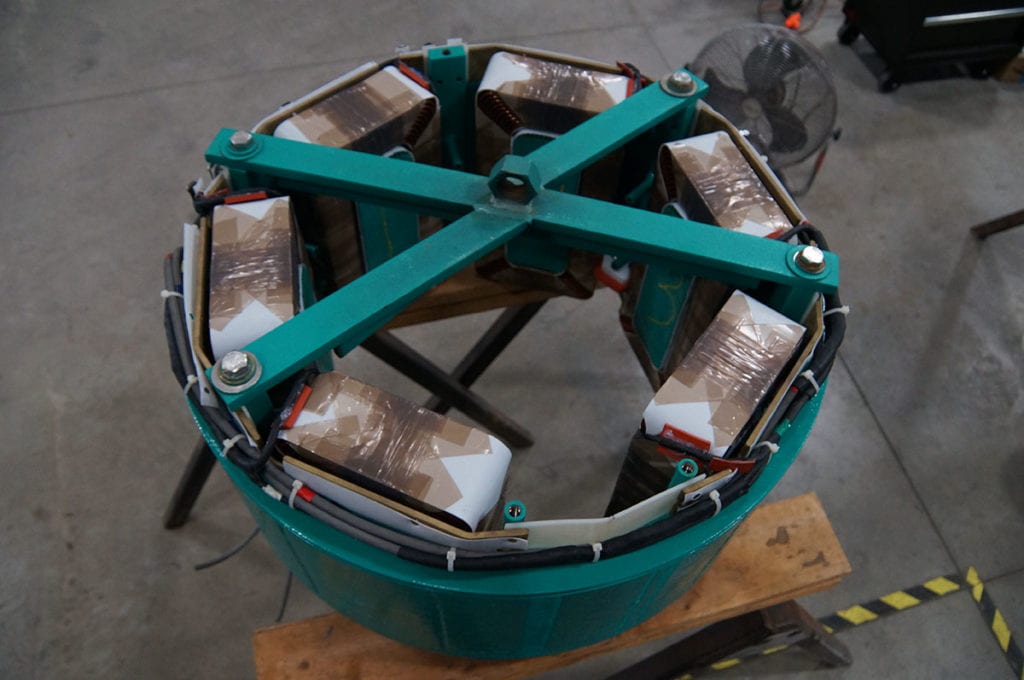

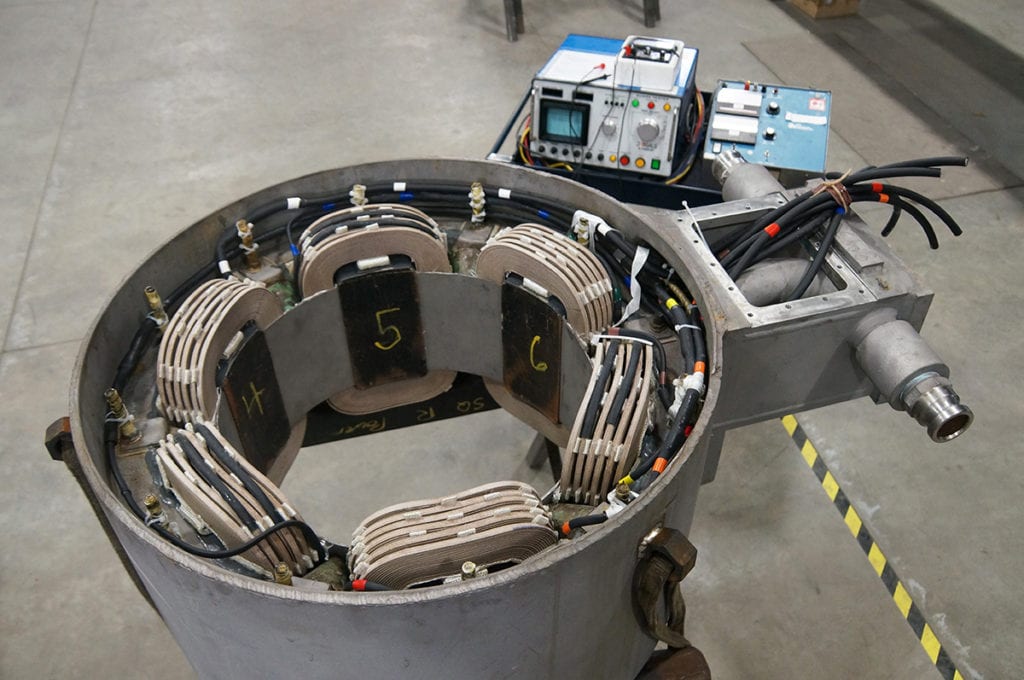

Ladle Stirrers

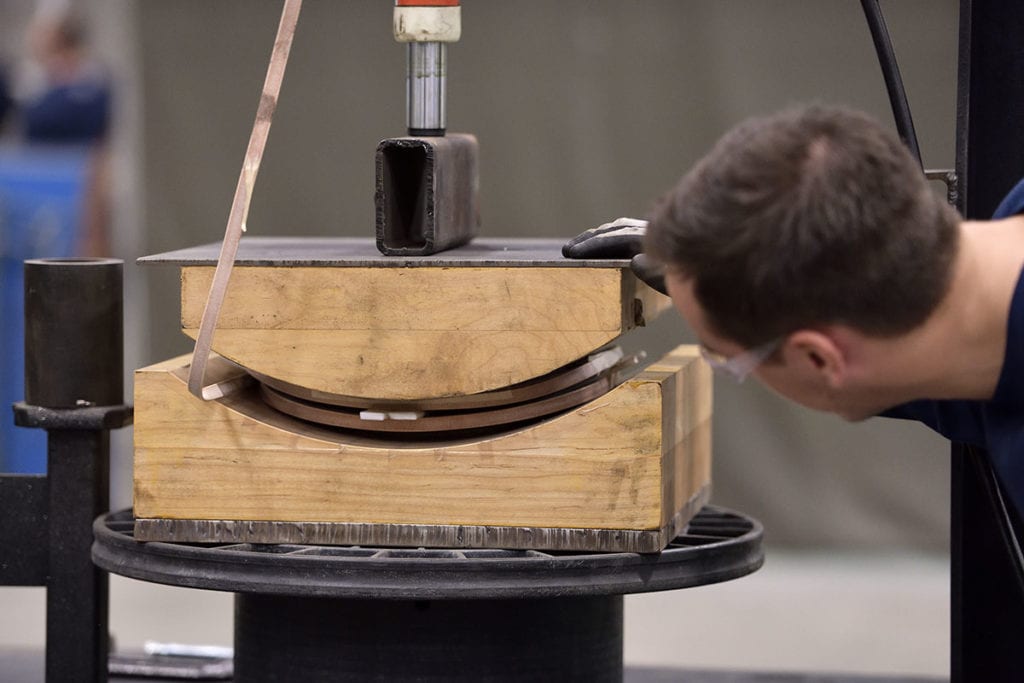

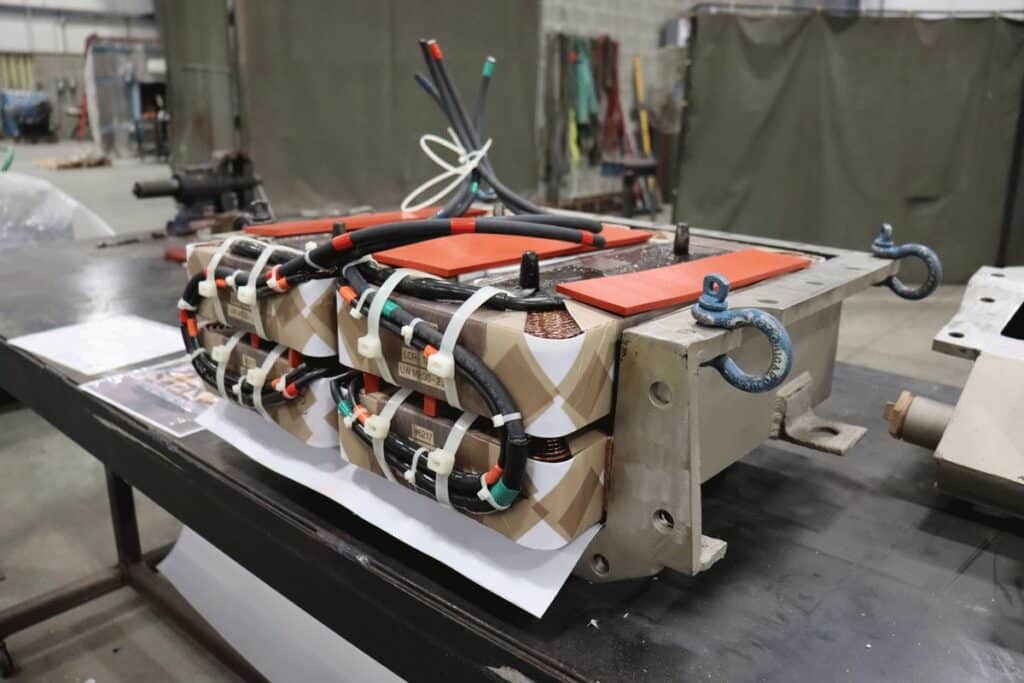

Servicing of ladle stirrers can be costly and can take weeks. The step-by-step remanufacturing of your EMS device must ensure dielectric integrity for optimum metallurgical control. Experienced and skilled technicians are well versed in challenging operating conditions and necessary improvements to rebuild your ladle stirrer to maximize protection against ladle impact and molten metal spill.

Every ladle stirrer component must be secured and kept in a state of compression to survive inherent low-frequency, high-amplitude magnetic field interaction. At every sequence of construction, torque values and components requiring isolation are confirmed and recorded. The entire surface area on each of the multiple coil assemblies are electrically leak tested at 2.5 times working voltage and inter-turn isolation is confirmed by high-voltage surge testing. A comprehensive testing report, including surge wave images, are forwarded for your records.