Induction Power Cables

Maximizing your power transmission efficiency

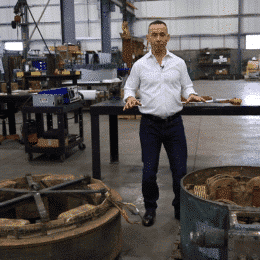

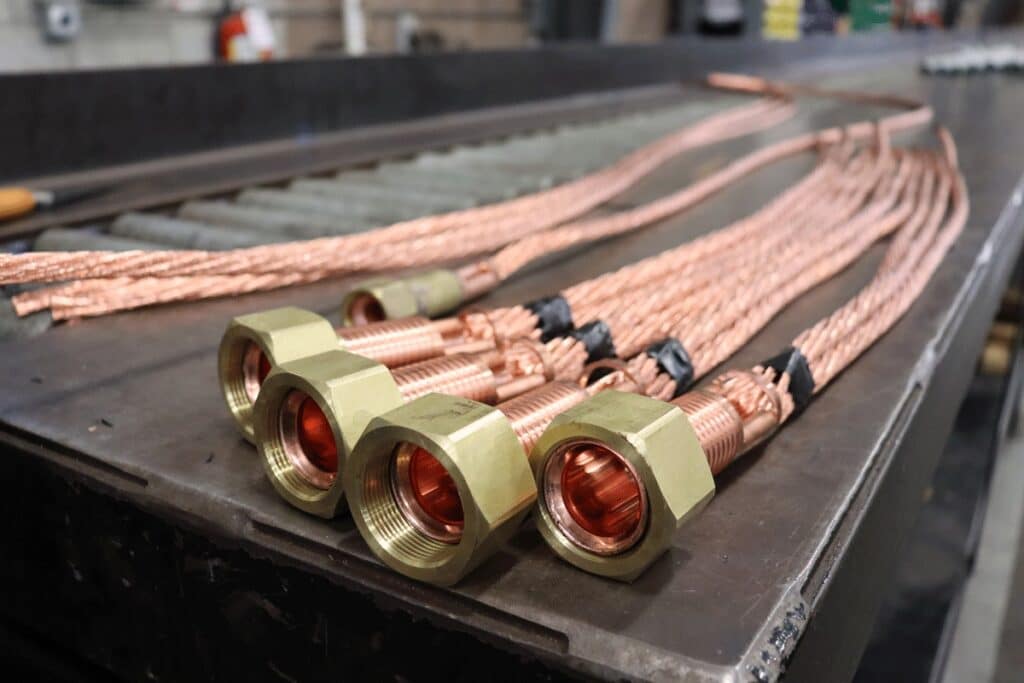

Engineered for electrical efficiency and hand-built using top-grade materials, I2r POWER technicians craft your high-current induction cables to maximize power transmission.

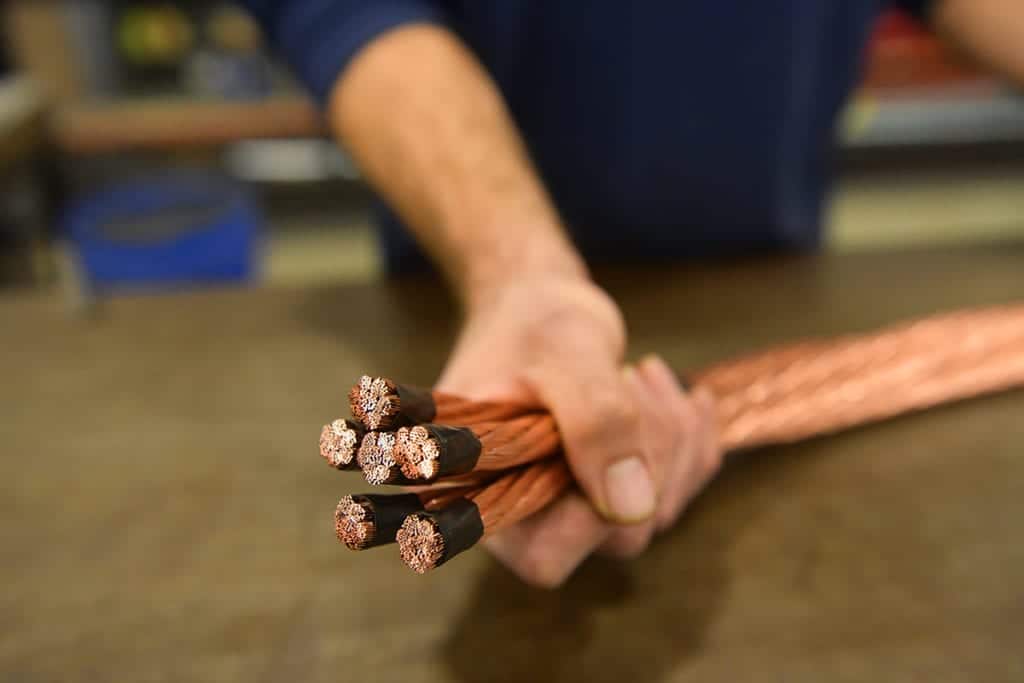

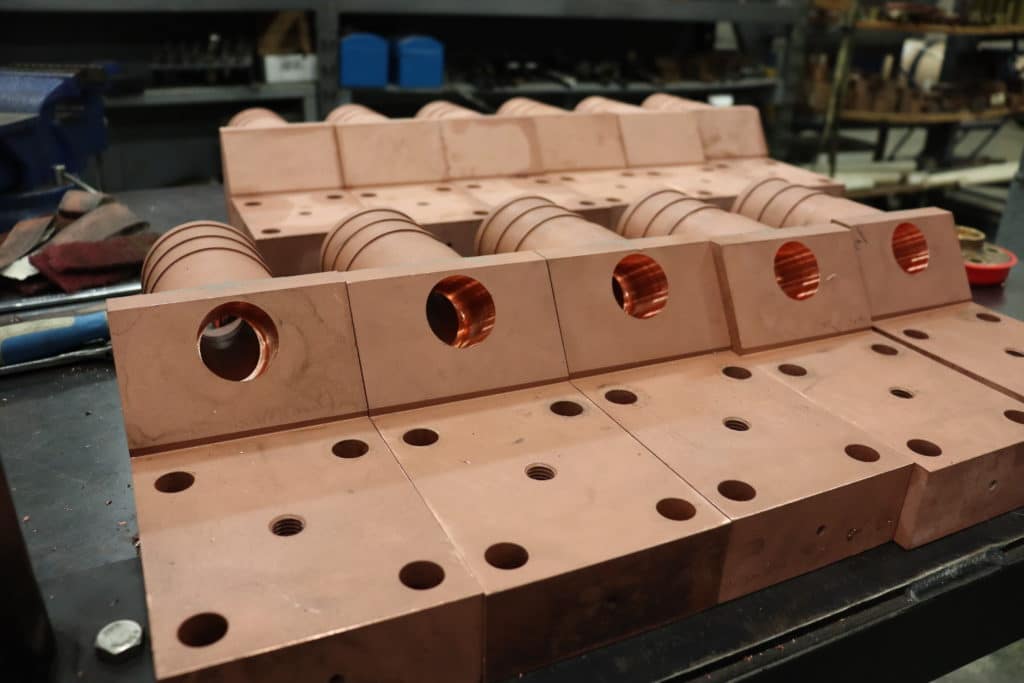

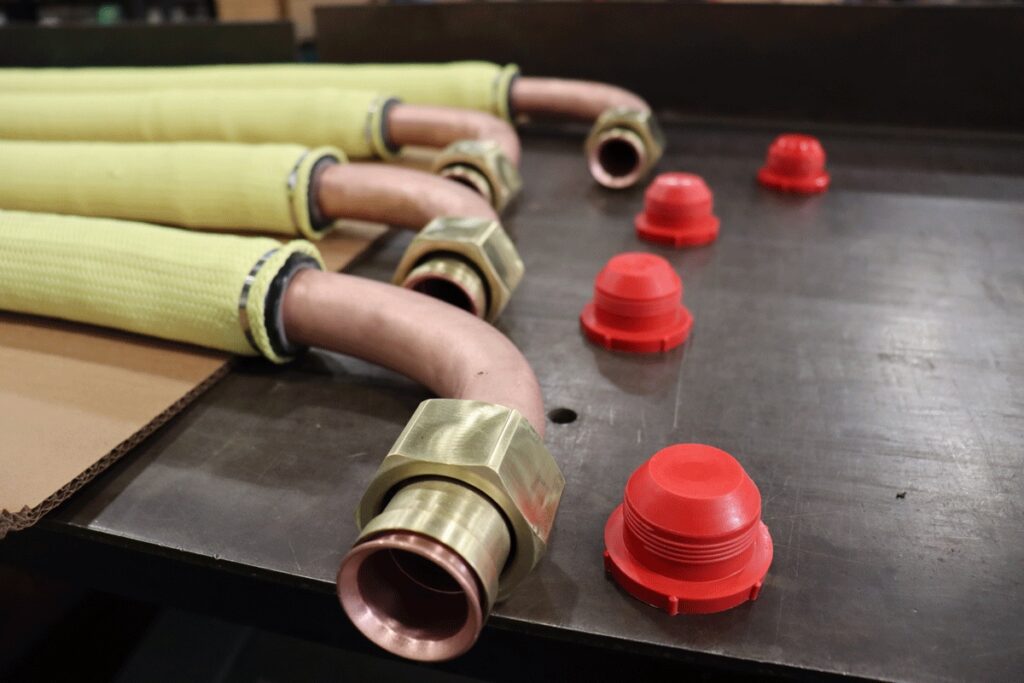

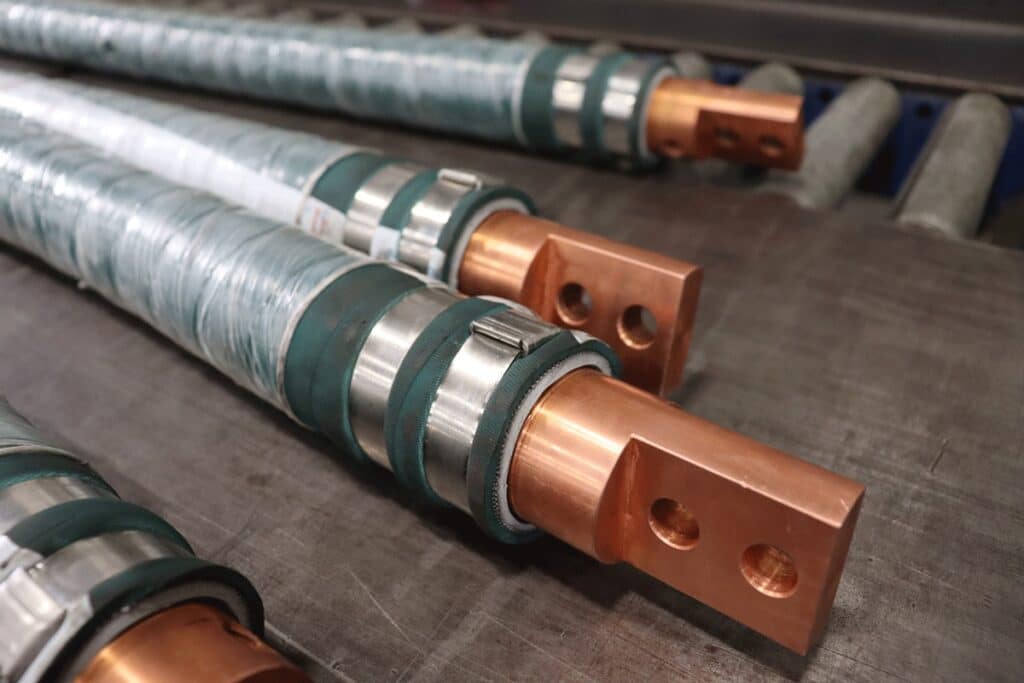

Sizing and construction of the air- or water-cooled conductor wire package is an engineered design effort at I2r POWER. Not only do properly built internal conductor packages and core structure have electrical efficiency advantages, I2r POWER designed cables maximize flexibility and incorporate external outer hose and protective coverings to withstand your demanding production conditions.

Entirely custom built to your exact specifications, I2r POWER solutions are always a collaborative effort. Routinely, electrical efficiency improvements are made during construction or repair of any induction system brand, type, or application to increase durability and extend cable life.

Whether looking for design, build, retrofit, or custom applications, I²r POWER is your best choice for induction process power cables.

Induction Power Cables Videos

Induction Power Cable Part #s, Specs & Measurements Decoded! (2020)

How Will I Know if my New Spares Work? (2020)

Protect the Flow of Your COOLANT! (2020)

Ensure Flow with Solder Pockets! (2021)

What Happens During a Cable Inspection? (2020)

Cable Protectin in the Worst Environments! (2021)

Water-Cooled Power Cables

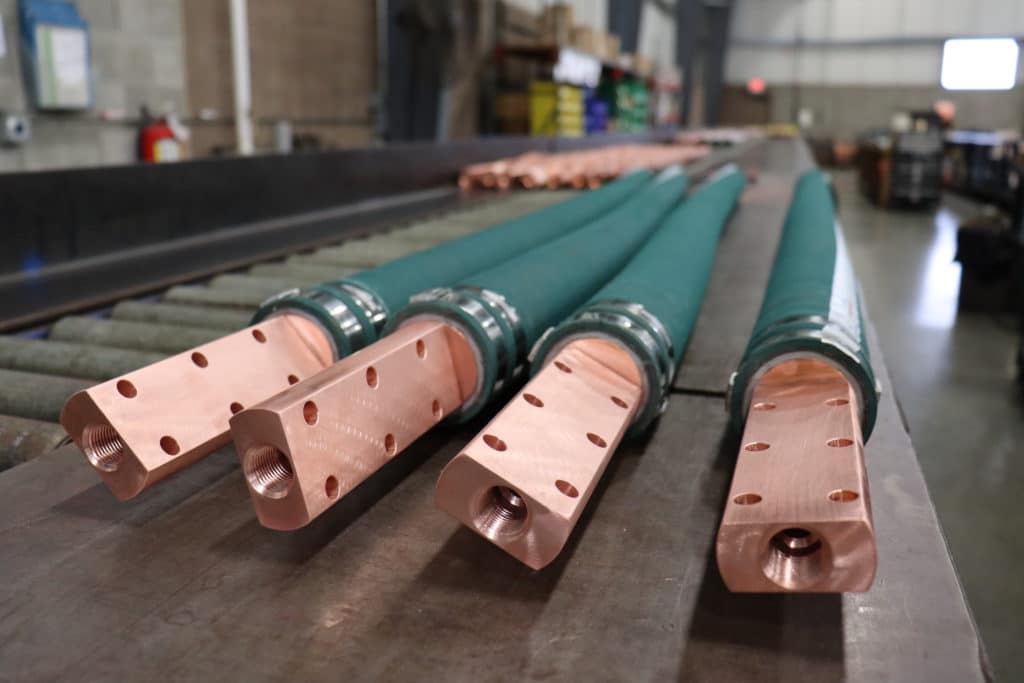

Optimal power transmission and electrical efficiency improvements are engineered into every water-cooled power cable at I2r POWER. No matter your application or demanding production environment, I2r POWER technicians hand-craft your water-cooled power cable for reliability and longevity.

Quality documentation is developed for all custom water-cooled cable jobs. Cables are flow, pressure, resistance-tested and visually inspected. Serial numbers are provided and photos are recorded before cables are prepared for shipping.

Since 2005, I2r POWER has been building water-cooled power cables for:

Steel Applications

- Electric Arc Furnace (EAF)

- Ladle Metallurgy Furnace (LMF)

- Submerged Arc Furnace (SAF)

Superalloy Applications

- Vacuum Induction Melting furnace (VIM)

- Vacuum Arc Remelting (VAR)

- Electro Slag Remelting (ESR)

- Precision Casting (DS/SC)

- DS/SX Equiax Casting

- Plasma Arc Melting (PAM)

- Electron Beam (EB)

- Sintering Processes

Foundry Casting Applications

- Coreless Induction Melting

- Channel/Holding Furnace

- Auto Pressure Pour Systems

- Graphite Stirring Rod Processes

Advanced Materials Applications

- Submerged Arc Furnace (SAF)

- Controlled Atmosphere

- Hot Isostatic Press (HIP)

- Sintering Processes

- Crystal Growth (Sapphire, Semi, Photovoltaic)

Air- to Water-Cooled Power Cable Conversions

When production processes demand, it may be possible to convert your air-cooled cables to water-cooled power cables. Please contact Mike Pinney or Karl Schwenk for more details about cable conversions.