How much torque to apply when installing induction cables?

How much torque to apply when installing induction cables

Often we’re asked for recommendations when tightening or loosening fittings on an induction power cable. First, this is a job for two wrenches! And, depending on your connection, be sure to avoid tightening or loosening soldered pipe threads.

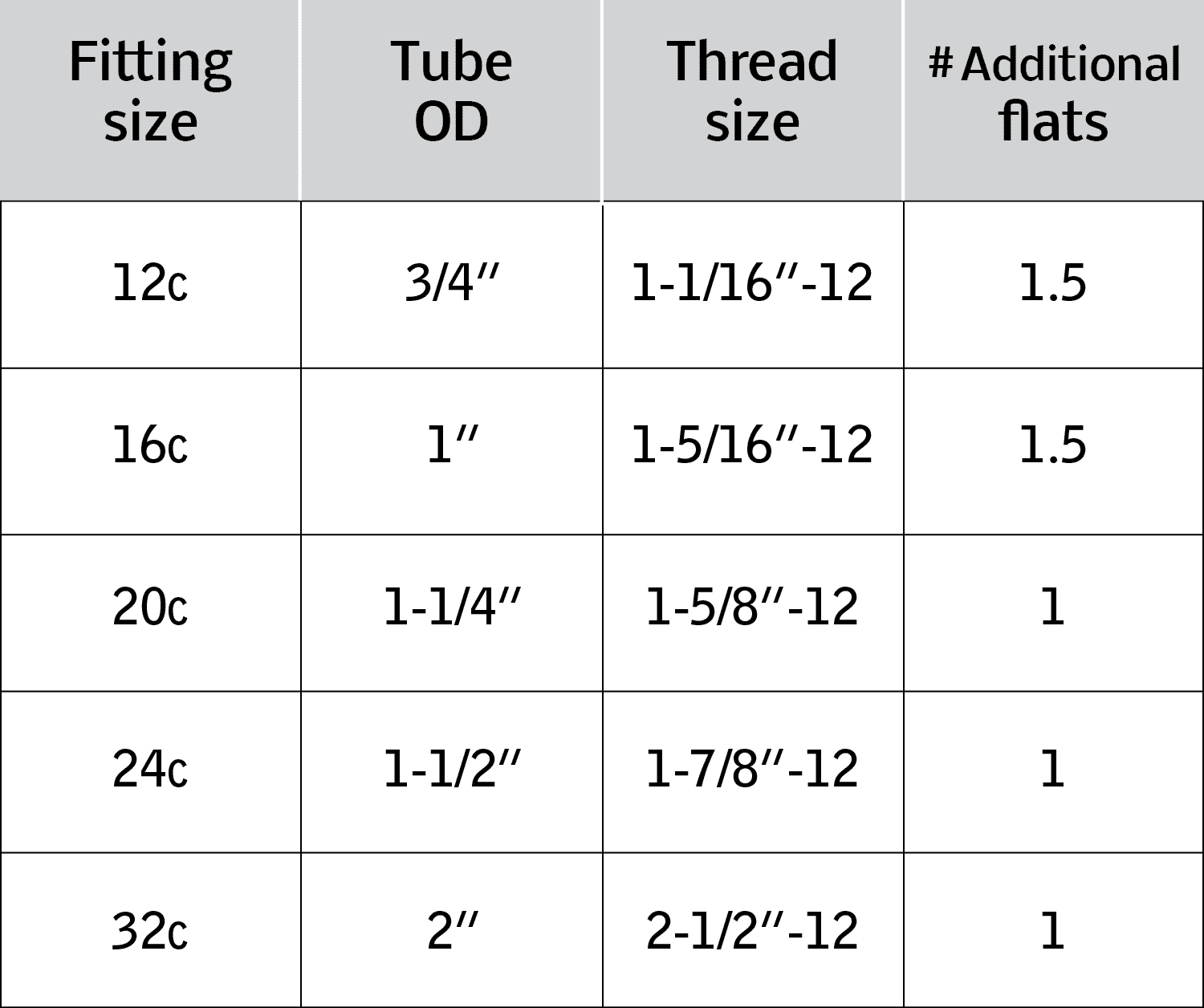

Here is the procedure for applying torque to standard 37-degree flared tube connections.

- Assemble components hand tight.

- Tighten the nut lightly with a wrench (approximately 30 inch-pounds.) This is the WR (wrench resistance) position.

- From the WR position, tighten the nut further using the number of flats recommended from the table graphic. Note: One flat is equal to 1/6 of a turn.

Eager to solve problems, I2r POWER’s technical team is more than willing to help you unravel your challenges.

Have questions about this topic?

More Articles

Power Cable Donation to Kent State enhances student experience

Power Cable Donation to Kent State enhances student experience I2r POWER recently provided two new sets of water-cooled power cables to the foundry and metal casting facility at Kent State University’s College of Aeronautics and […]

Read MoreEnd-of-Year Holidays Time to Express Gratitude

End-of-Year Holidays Time to Express Gratitude It’s time to celebrate a successful, though at times difficult, year! We made it! The company holiday party is an ideal time to share our gratitude for all those […]

Read MoreElectromagnetic caster stirrer designs vary depending on use

Electromagnetic caster stirrer designs vary depending on use Electromagnetic stirrers for steel applications produce very low frequency, high amplitude magnetic fields to agitate steel when molten. Steel applications include ladle stirring and stirring in continuous […]

Read More