Electromagnetic caster stirrer designs vary depending on use

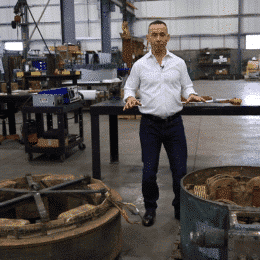

Electromagnetic stirrers for steel applications produce very low frequency, high amplitude magnetic fields to agitate steel when molten. Steel applications include ladle stirring and stirring in continuous cast steel for alloy integrity. Always under water during operation, cooling water wicks the heat away from these induction coil sets.

Depending on how the stirrer is used and the effects desired, caster stirrer design options begin with some of these basic differences.

Stater or Core Assembly design options:

- Removable from the outer casing weldment

- Permanently attached to the interior of the casing weldment

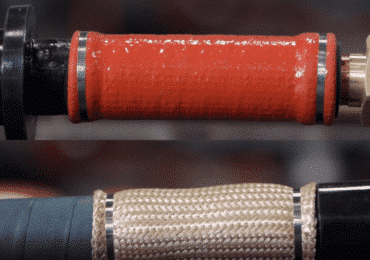

Conductor/Magnet wire options include:

- Flat shaped conductor with both polyester and KaptonTM dielectric insulation coatings

- Round shaped conductor with a Kapton dielectric insulation coating

When caster stirrers come through the shop, we conduct several electrical tests to establish a baseline for each individual caster stirrer before we begin disassembly. Conducting these tests helps us in our quest to determine the root cause of failure. We document the disassembly and share details and findings with our customers.

I cover this in more detail in a video. Watch here in our Video Gallery or on YouTube.

Let us know how we can help you restore your electromagnetic caster stirrer!

Eager to solve problems, I2r POWER’s technical team is more than willing to help you unravel your challenges.

Have questions about this topic?

More Articles

Power Cable Donation to Kent State enhances student experience

Power Cable Donation to Kent State enhances student experience I2r POWER recently provided two new sets of water-cooled power cables to the foundry and metal casting facility at Kent State University’s College of Aeronautics and […]

Read MoreEnd-of-Year Holidays Time to Express Gratitude

End-of-Year Holidays Time to Express Gratitude It’s time to celebrate a successful, though at times difficult, year! We made it! The company holiday party is an ideal time to share our gratitude for all those […]

Read MoreCable Protection in Induction Melting Applications

Cable Protection in Induction Melting Applications Protecting your induction power cables from harsh metal casting conditions is critical. Water-cooled power cables are subjected to ambient heat, molten metal splash and spills, and chafing and friction. […]

Read More