Electromagnetic stirrers for steel applications produce very low frequency, high amplitude magnetic fields to agitate steel when molten. Steel applications include ladle stirring and stirring in continuous cast steel for alloy integrity. Always under water during operation, cooling water wicks the heat away from these induction coil sets. Depending on how the stirrer is used…

View PostPowering Your Process

Read all articles in the blog category Powering Your Process

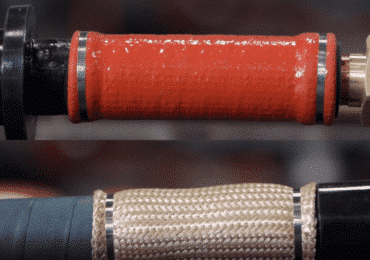

Cable Protection in Induction Melting Applications

Protecting your induction power cables from harsh metal casting conditions is critical. Water-cooled power cables are subjected to ambient heat, molten metal splash and spills, and chafing and friction. We see a lot of used cables come through the shop showing signs of extreme wear. A variety of protective sleeving solutions are available to metal…

View PostEAF/LMF Cable Protection for Steel Makers

A lot of EAF water-cooled power cables come through the shop showing signs of extreme wear and tear. There's no avoiding it, steel making environments are demanding on equipment. The dirt, heat, and collisions are inevitable. Typically, failed cables suffer from ambient heat, molten metal splash and spills, and chaffing and/or friction. A variety of…

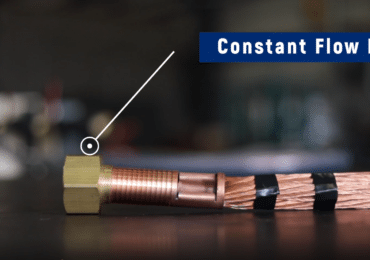

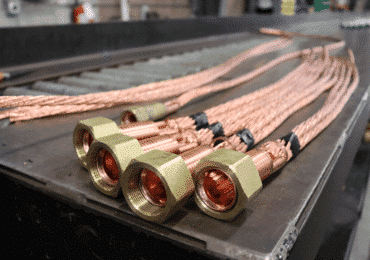

View PostCFR rings are a must for swivel nut terminal designs

The lifeblood of any induction melting system is coolant. Loss of coolant in an induction system creates all kinds of issues, and none of them are good. We see a lot of coolant flow disasters come through the shop. To ensure coolant flow at I2r POWER, we employ the Constant Flow Ring (CFR) in our…

View Post3 Tests to ensure your spare Induction Power Cable performs

I'm often asked by customers, "How will I know my induction power cable is going to work when needed?" There's a lot of money spent on spare components, and power cables are no exception. When they are needed, they are NEEDED! And if the cables don't work when required, it can be catastrophic. There are…

View PostInduction power cable terminal design options

Metal casting power needs are as varied as each induction melt system and application. The good news is you've got power cable design options! The industry standard is a conventional crimped, swivel nut design. At I2r POWER we recommend promoting better coolant flow by building into this design a Constant Flow Ring (CFR). A CFR…

View PostAvoid EAF Cable Failure by Relieving Torsion!

A majority of the electric arc furnace power cables we inspect have the most damage at the transformer vault end of the cable. The copper conductor package and heavy cover hose typically have suffered excessive wear due to torsional force or twisting of the cable when the conductor arms and furnace roof swings back and…

View PostWhat happens during a cable inspection?

Steps go something like this: You send in your used induction power cable. We'll open it up. Remove the cover hose. We'll expose the conductor. But more importantly, I believe there's a deeper understanding that power cables can give us. Power cables are the arteries of an induction melting system. Just like high blood pressure…

View PostKeep Your EAF/LMF Power Cable Spares Ready for a Really Bad Day

The unthinkable has just happened. You got the word that a power cable needs to be replaced, and NOW! So…where are the spares? Are they in the storeroom? Behind the furnace? Outside in the yard? Here's what I'm hoping you'll find: Spare cables are laying flat in stackable trays or suspended vertically to maintain wire…

View PostHow to measure your power cable length

There's more than one way the industry measures induction power cables, unfortunately creating confusion. Some measure the hose length. We prefer to go with the overall length, and by that we mean we measure from copper terminal flare to the terminal flare edge on the other side of the cable. This flare-to-flare method is an…

View PostHow much torque to apply when installing induction cables?

How much torque to apply when installing induction cables Often we’re asked for recommendations when tightening or loosening fittings on an induction power cable. First, this is a job for two wrenches! And, depending on your connection, be sure to avoid tightening or loosening soldered pipe threads. Here is the procedure for applying torque to…

View PostWork In Progess: Intricate Bus for Tight Quarters

Custom Bus for Tight Quarters Problem: This high capacity titanium producer was facing limited space for a bus system carrying 40,000 amps and it's cooling interconnections in a new Vacuum Arc Remelt (VAR) system. Solution: Using modeling software, I2r POWER engineers were able to design a series of cooling passages for a large section of bus. Heat…

View Post