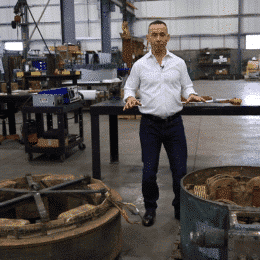

Induction Furnace

Engineered solutions for your application

Demanding environments require equipment with built-in protection and reliability. Durability and longevity of your water-cooled induction power cables are critical to meeting your production requirements. Induction furnace power cables from I2r POWER are designed to withstand harsh operating conditions with no leaks, no chafing, and resistance to molten metal spill.

Put I2r POWER’s long history of expertise to work engineering a solution fit for your induction furnace production. Water-cooled power cable repairs and new builds are tested at each hand-built stage to ensure they are free from leaks, are performing efficiently, and your productivity is not compromised.

Induction Furnace Videos

Induction Power Cable Part #s, Specs & Measurements Decoded! (2020)

How Will I Know if my New Spares Work? (2020)

Protect the Flow of Your COOLANT! (2020)

Cable Protection in the Worst Environments! (2021)

What Happens During a Cable Inspection?

Induction Furnace Power Cables to Withstand Your Demanding Conditions

A range of protective external hose coverings and construction materials are applied to fit your exact production requirements. I2r POWER keeps a wide inventory of materials in stock and at the ready. Inherent chafing can be minimized and flexibility can be maximized with the right choice of specially designed materials. Molten metal splash in many cases is inevitable. I2r POWER designs induction power cables to withstand your demanding operating conditions, increasing durability and extending cable life.

Rigid Bus Systems for High Value Power Transmission

Rigid induction furnace bus systems are handcrafted for high value, long lasting power transmission. Entirely custom built to your exact specifications, I2r POWER technicians hand-build bus bar and bus tube systems to ensure even power distribution, reliable performance, and system longevity. I2r POWER makes system efficiency improvements to ensure a compact, robust, low maintenance design, and to minimize unwanted inductive heating of adjacent equipment.

Collaborative Engineered Design Effort for Best Induction Furnace Performance

Whether your need is for design, build, retrofit, or custom applications, I2r POWER solutions are always a collaborative, engineered effort. Skilled technicians routinely craft induction power cable improvements into repair and rebuilds of any induction system brand, type or application power cable.

The goal at I2r POWER is to optimize electrical efficiency and ensure power cable integrity. Engineered to meet your exact specifications, let’s collaborate on what environmental protection and electrical efficiency solutions you need for your induction furnace process.