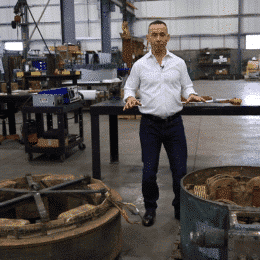

Notable Project: TimkenSteel – Harrison Mill Final Stirrer

TimkenSteel - Harrison Mill Final Stirrer

Problem: Caustic flux powder used in the continuous casting process was violently attacking the carbon steel weldment of TimkenSteel’s electromagnetic final stirrer.

Solution: A new weldment of high-grade corrosion-resistant stainless alloy was designed, built and fabricated to stop corrosion. It’s not out the door yet, because we’re storing it for our customer.

Eager to solve problems, I2r POWER’s technical team is more than willing to help you unravel your challenges.

Have questions about this topic?

More Articles

Power Cable Donation to Kent State enhances student experience

Power Cable Donation to Kent State enhances student experience I2r POWER recently provided two new sets of water-cooled power cables to the foundry and metal casting facility at Kent State University’s College of Aeronautics and […]

Read MoreEnd-of-Year Holidays Time to Express Gratitude

End-of-Year Holidays Time to Express Gratitude It’s time to celebrate a successful, though at times difficult, year! We made it! The company holiday party is an ideal time to share our gratitude for all those […]

Read MoreElectromagnetic caster stirrer designs vary depending on use

Electromagnetic caster stirrer designs vary depending on use Electromagnetic stirrers for steel applications produce very low frequency, high amplitude magnetic fields to agitate steel when molten. Steel applications include ladle stirring and stirring in continuous […]

Read More