How do I size my cable?

In order to size your cable, you should first measure the length required to make the connection between the power source and the heating/melting device.

Next, calculate the amount of copper conductor required to carry the current. A water-cooled cable and/or bus, needs approximately 350 MCM of copper cross-section for every 1,000 amps of current. Conversely, an air-cooled system requires approximately 3 times the copper conductor to carry the same current. Induction-based melt systems must consider the operating frequency into account, when determining the optimal conductor cross-section.

Get answers and more information on specific types of cables below…

How do I size my induction cable?

To properly size your induction power cable, measure from the terminal flare to terminal flare for total length adequate for to make the connection between the power source and the induction furnace.

A water-cooled induction cable needs approximately 350 MCM of copper cross-section for every 1,000 amps of current. Conversely, an air-cooled system requires approximately 3 times the copper conductor to carry the same current. Induction-based melt systems must consider the operating frequency into account, when determining the optimal conductor cross-section.

This applies to the following types of water-cooled power cables:

- Furnace cable

- Furnace power cable

- Induction cable

- Induction power cable

- Induction furnace cable

- Induction furnace power cable

Induction Power Cables

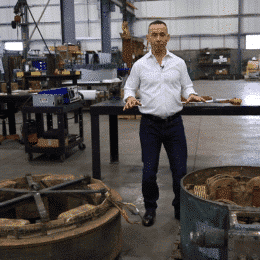

Engineered for electrical efficiency and hand-built using top-grade materials, I2r POWER technicians craft your high-current induction cables to maximize power transmission. Learn more.

How do I size my electric arc furnace (EAF/LMF) cable?

To properly size your electric arc furnace (EAF) cable or ladle metallurgy furnace (LMF) cable, measure from terminal end to terminal end for total length.

A water-cooled EAF power cable needs approximately 350 MCM of copper cross-section for every 1,000 amps of current. Conversely, an air-cooled system requires approximately 3 times the copper conductor to carry the same current.

This applies to the following types of EAF/LMF water-cooled power cables:

- Electric Arc Furnace cable

- Electric Arc Furnace power cable

- EAF cable

- EAF power cable

- Ladle Metallurgy Furnace cable

- Ladle Metallurgy Furnace power cable

- LMFcable

- LMF power cable

EAF/LMF Power Cables

Optimal power transmission and electrical efficiency improvements are engineered into every Electric Arc Furnace (EAF) and Ladle Metallurgy Furnace (LMF) water-cooled power cable at I2r POWER. No matter your high-current application or demanding production environment, I2r POWER technicians hand-craft your water-cooled power cable for reliability and longevity. Learn more.

Have additional questions?

I2r POWER works hard to over-deliver on customer expectations. Every job is a custom, engineered design effort to fit your exact specifications. Collaborating to solve customer problems is how we do it. We want to hear from you! Contact us today to get more information or request a quote.